With the Bespoked customized bike present returning to Dresden beginning tomorrow, let’s have a look inside Actofive Cycles, who machines stunning mountain bikes within the German metropolis. We’ve been intently following Actofive for a couple of years – from the event of their variable journey path to enduro bikes, to their chainrings and modular cranksets. However we additionally had the distinctive likelihood to get a better look behind the scenes on one in all our final visits to Dresden.

Take a look at these machined aluminum gems with us, and a few uncommon up-close seems on the within their machined masterpieces…

Actofive Manufacturing facility Tour: CNC-machining mountain bikes in Dresden, DE

Totally CNC-machined, Actofive produces a few of the most refined mountain bikes you will see that anyplace within the biking trade. However they’re truly fairly a small specialist producer, sitting inside an previous industrial constructing on the sting of Dresden, Germany.

Beneath, these old-school riveted metal trusses and tucked in with a number of different forms of small producers is a extra up to date field hiding the trendy capabilities of Metzner Engineering and the house of Actofive Cycles.

As soon as contained in the interior sanctum, numerous Actofive fashions and growth prototypes cling on the wall of the unassuming workshop.

Metzner Engineering: The person behind the machine

Actually, there are 2 secrets and techniques that make Actofive.

One is the person behind the model, Simon Metzner. And the opposite, the exact Portatec CNC milling machine. Working collectively, these two create each Actofive mountain bike and element.

The CNC-machine and a number of other of its distinctive options are produced by the corporate of Simon’s father, primarily for the aerospace trade. However as a substitute of taking on the enterprise, Simon all the time had different concepts of the best way to use these machines. And with mountain biking being his ardour, Simon Metzner went out on his personal to begin up Metzner Engineering, a contract CNC-manufacturing firm created to permit him to additionally additional his MTB element and bike growth.

So by mixing his experience in manufacturing course of optimization, the CNC capabilities of his small workshop, and deep mountain bike design information, Simon has developed Actofive right into a sought-after small German mountain bike producer creating true CNC-machined MTB gems.

From prototype to manufacturing

We have been first actually launched to Actofive’s high-pivot alloy P-Prepare about 3 years in the past. However Simon has been engaged on that first adaptable-travel enduro bike for no less than a couple of years longer, since 2018. That’s when he frolicked his personal shingle as Metzner Engineering, after leaving the household CNC machine manufacturing enterprise.

In its first iteration, the bike began with a welded metal entrance & rear triangle joined along with CNC-machined alloy hyperlinks. And it has continued to evolve in lots of iterations alongside the best way. That unique metal bike now sits in Simon’s workplace with a machined rear finish fairly much like right now’s manufacturing P-Prepare.

And whereas CNC-machining aluminum has all the time been type of in Simon’s blood, he isn’t solely beholden to 1 materials, and even the subtractive machining course of. He’s toyed with different supplies – like titanium – and in addition with the potential of contemporary 3D-printing capabilities.

However machining aluminum has outlined the event of Actofive’s bikes and elements these final 6 years, particularly using intricate and well-thought-out milling designs. And it types the idea for Actofive’s distinctive clamshell, or sandwich building.

And Simon continues to indicate that he has extra concepts on the best way to refine each his designs and their manufacturing. So there’s a lot evolution left to do in CNC-machined aluminum.

Inside Actofive’s manufacturing facility tour: MTB components in-process

Wanting across the Actofive workshop throughout our manufacturing facility tour confirmed a fairly good pattern of their full providing, in numerous phases of completion.

Listed below are a few I-Prepare path bike entrance triangles. The 2 halves have every been machined from each side – the surface that we are able to see, plus the intricate inside webbed truss construction that Actofive doesn’t let anybody else see.

We had a peek, and it’s much more spectacular that the positive device marks you see on the surface. The design of the interior construction permits Actofive the flexibility to fine-tune energy and stiffness at numerous areas throughout the mountain bike body, whereas retaining it light-weight.

However Actofive is cautious of freely giving the secrets and techniques of how they obtain their steadiness of lightweight-to-strength. And particularly resistant to provide away the design of their interlocking system that’s used to bond the 2 halves of a body collectively to create the whole bike.

We additionally had an opportunity to look at some Actofive crankarms be machined of their first step throughout our manufacturing facility tour.

From alloy slabs to machined gems

The center of every little thing that Actofive produces begins out as easy slab of aluminum billet.

And actually, most of Actofive’s elements come all the way down to machining one facet to get the ultimate exterior form. Then, flipping it over (and securing it to a unfavorable fixture on the milling machine) to hole out the second facet.

The best components like their extra inexpensive Signature X crankset, the P-train rear finish, and the I-Prepare seatstays go away it at that, the place you possibly can see each side which have been machined. However extra complicated hole components just like the mountain bike entrance triangles & Signature cranks, get 2-sided machining for every body half which are then bonded collectively to create the extra complicated hole construction.

However after all, transferring large heavy chunks of aluminum round is sort of troublesome earlier than all that additional materials is machined away (and picked up for recycling). So Actofive has this good little crane of their machining room, which permits Simon the flexibility to simply maneuver every little thing on his personal.

After which, as soon as held down on the milling machine’s worktable with a powerful vacuum strain, the intricate designs could be carved out of the uncooked billets of aluminum. Most frequently in densely packed, nested layouts to optimize probably the most quantity of elements out of a single piece of uncooked aluminum materials.

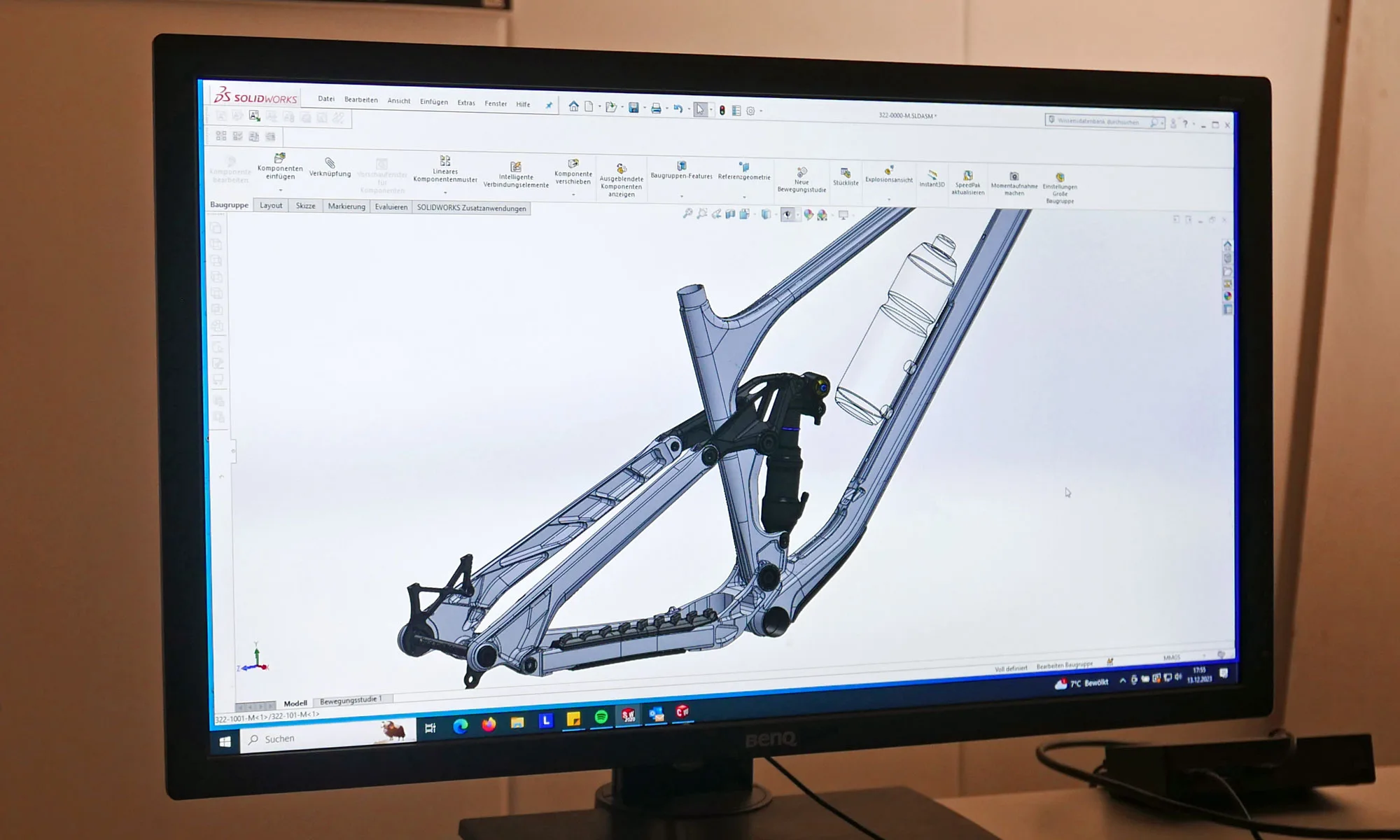

CAD upstairs + CAM downstairs

Every thing that Actofive produces in made in-house within the manufacturing facility that we toured.

Simon has a design workplace upstairs straight over his machining room.

There every little thing is designed and refined in SolidWorks, creating the computer-aided design (CAD) knowledge to drive the computer-aided manufacturing (CAM) processes one flooring under.

ActoFive’s key manufacturing outputs…

Actofive’s specialty is creating 3 issues. CAD/CAM knowledge, metallic filings, and out of that… precision machined alloy elements.

The Portatec CNC mill is the brawn. However the brains of the Siemens controller manages all of the machining processes, tooling, and the place these device lower. Whereas Simon can remotely function every little thing from his laptop upstairs, for manufacturing, every little thing is dealt with straight on the machine. There’s a lot uncooked knowledge governing the machining course of, this ensures that any potential minor breakdown in communication couldn’t negatively have an effect on the ultimate work.

In addition to knowledge, Actofive’s manufacturing facility is roofed with these small aluminum filings we noticed in our tour.

Positive, the majority of fabric will get effectively collected for recycling, however loads of chips fly round. That’s why machining occurs in its personal utterly enclosed room. However each time Simon strikes round to manage the method, filings keep on with his garments & sneakers. And since they’re not magnetic, it’s a chore to completely preserve below management.

So he has separate garments and sneakers for engaged on bikes & elements within the store. And simply resigns himself to common cleansing and swapping to separate clothes earlier than leaving the workshop.

Lastly, specialised machined alloy elements. Actofive is the bike model that drives Simon Metzner’s ardour. And from that we get full-suspension Actofive mountain bike frames, cranksets & chainrings.

However he does loads of contract manufacturing too. There’s actually a little bit of crossover within the bike trade – issues like bashguards, prime caps, and even some extra superior components like rocker hyperlinks & seatstays for different bike firms. However there’s loads of different industrial machining, too. Simon defined that he spends the overwhelming majority of his growth and manufacturing time on the Actofive mountain bike facet of issues, however nonetheless greater than three-quarters of his revenue comes from contract machining.

Actofive Manufacturing facility Tour: MTB cranks, chainrings & frames

Signature X cranksets have been a giant shift in making Actofive elements extra inexpensive, from slightly below 400€.. or half the price of the unique hole Signature cranks.

Actofive direct mount chainrings add 120-150€ on prime of that.

The rocker hyperlink on the I-Prepare is one other nice instance of Actofive’s inventive 2D manufacturing. Like most of their MTB elements, it’s made by merely matching two halves (from each side) which are then joined along with a easy keyed interface and a single bolt for easy energy.

MTB frames begin from 6000€ for the less complicated I-Prepare body set. A P-Prepare will set you again no less than 7000€.

Curiously, one method to come up with an Actofive mountain bike body for a bit cheaper is likely to be to put your palms on a present demo. With Bespoked on the horizon, Actofive is providing offers of their on-line store on earlier variations of the I-Prepare that have been already proven. And they’re even providing the customized mk2 I-Prepare bike prematurely, that can be on show within the Dresden Airport present over the weekend.

Anodized eye sweet colours

After all, one of many cool advantages of an all-machined-alloy mountain bike (or elements) is the flexibility for some flashy anodized finishes. Actofive has a companion handle their eye-catching colours, however they will even do some enjoyable stuff with two-done finishes one facet to the opposite.

I particularly just like the half blue + half silver race bike of Czech enduro World Cup racer y Vojta Bláha/DVO who confirmed off his bike to us for the DVO Prime launch earlier this summer season.

Contained in the precise clamshell Actofive mountain bikes…

OK, so right here’s an actual uncommon sneak peek inside an Actofive…

This crimson/orange I-Prepare entrance triangle is manufactured in 2 halves with a clamshell design. By machining all sides individually, Actofive can creates the precise clean outer form that they need for the bike, however can fluctuate thicknesses all through numerous sections of the body, very similar to you discover with butted tubing.

However in actuality, the within of the I-Prepare is way more complicated that that, that includes a sequence of reinforcing webs that change the tube wall thickness way more than might be achieved by any tube-to-tube type building.

After which the actual secret comes with the mechanically overlapping finger joint from one facet of the body to the following. This significantly will increase the floor contact space between the 2 halves, leading to a powerful bond when the body is assembled with adhesive. And it additionally reinforces the joint on the prime and backside edges of the body, defending it towards influence with rocks or different obstacles.

One factor I actually love about Actofive’s bikes is how one can see the machining marks that present how the CNC tooling cuts forwards and backwards into the aluminum billet. However after all, since they machine the within of the body simply as a lot as the surface, our Actofive manufacturing facility tour additionally gave us an up-close glimpse at how these device paths are even seen within the body.

Like on the within of this I-Prepare’s headtube.

What comes subsequent for Actofive?

That was just about it for our Actofive manufacturing facility tour. We received to look at some Signature X cranksets be machined – 60 crank arms at a time in that batch. And Simon revealed us a little bit of what was coming quickly this yr. Suppose UDH compatibility throughout all frames, after all, together with the flexibility to retrofit the entire frames they’d beforehand produced. And these newly machined, open-back seatstays that changed the I-Prepare’s unique welded tubing stays.

Plus, there’s much more that we are going to see over the approaching looking for with extra next-gen P-Prepare & I-Prepare updates.

Keep tuned for that!

Actofive after darkish

And with that, we’ll go away you with Actofive ‘After Darkish’.

A lot of Actofive’s CNC-machining processes take 8 hours or extra to finish. So Simon tries to schedule it in order that he can arrange a machining activity on the finish of his workday, to run in a single day. And he’ll usually even lowering device speeds a bit to make sure much less likelihood of any hassle when the machines are left to work on their very own.

Actofive has a webcam within the machining room so Simon can dial-in to maintain tabs on progress – whether or not he’s upstairs working at his desk on one other venture, or again dwelling for the evening.

And whereas the lights exit within the human facet of the Actofive workshop, the sunshine usually stays on all evening because the CNC robotic chugs away, machining mountain bikes by means of the lonely evening.